Contents

Single Pin

Double Pin / Cradles for Augers

Dedicated Quick Connect – Kubota, John Deere, Bobcat, Wain Roy

S Type – Tiltrotators

Fully Hydraulic Coupler Systems

Single Pin Mounts

The cheapest and most simple way to mount an attachment to your excavator is through a single pin hitch that pins through the stick of the machine. This would replace your bucket main pin and allow the attachment to swing freely from the machine.

Of course, not all attachments can be mounted through 1 pin, the most common attachment that would be mounted this way would be an auger attachment. Other attachments like trenchers, shears, grabs etc. must be double pinned in order to change the position of the attachment. Augers mostly just need to hang vertically so the single pin is the fastest, cheapest option.

Other attachments that use a single pin system are clamshell buckets for material handlers, demolition grapples for use in scrap yards etc. Most attachments require more flexibility that working in the vertical position all of the time.

Double Pin

The most conventional system for mounting attachments on excavators is a double pin setup. One main pin through the stick of the machine and a second pin through the H link, lets the operator change the angle of the attachment. Conventionally this would have been the setup on the first excavators that only used buckets.

As mentioned earlier most attachments need to be mounted this way to allow more flexibility for the operator. However, what makes this mounting setup more complicated is the variation of pin dimensions across different manufacturers’ makes and models.

For example, even for a similar size machine, a John Deere excavator and a Caterpillar excavator will have different pin dimensions. We have an extensive list of machine’s pin dimensions available here.

Here is a rough guide of the pin diameters for machines based on weight class (rough guideline):

1.5 to 2.5 tons – 25-30mm

2.5 to 3.5 tons – 30-40mm

3 to 5 tons – 40-50mm

5 to 10 tons – 50-60mm

10-15 tons – 60-70mm

15 to 22 tons – 70-80mm

22 to 25 tons – 80-90mm

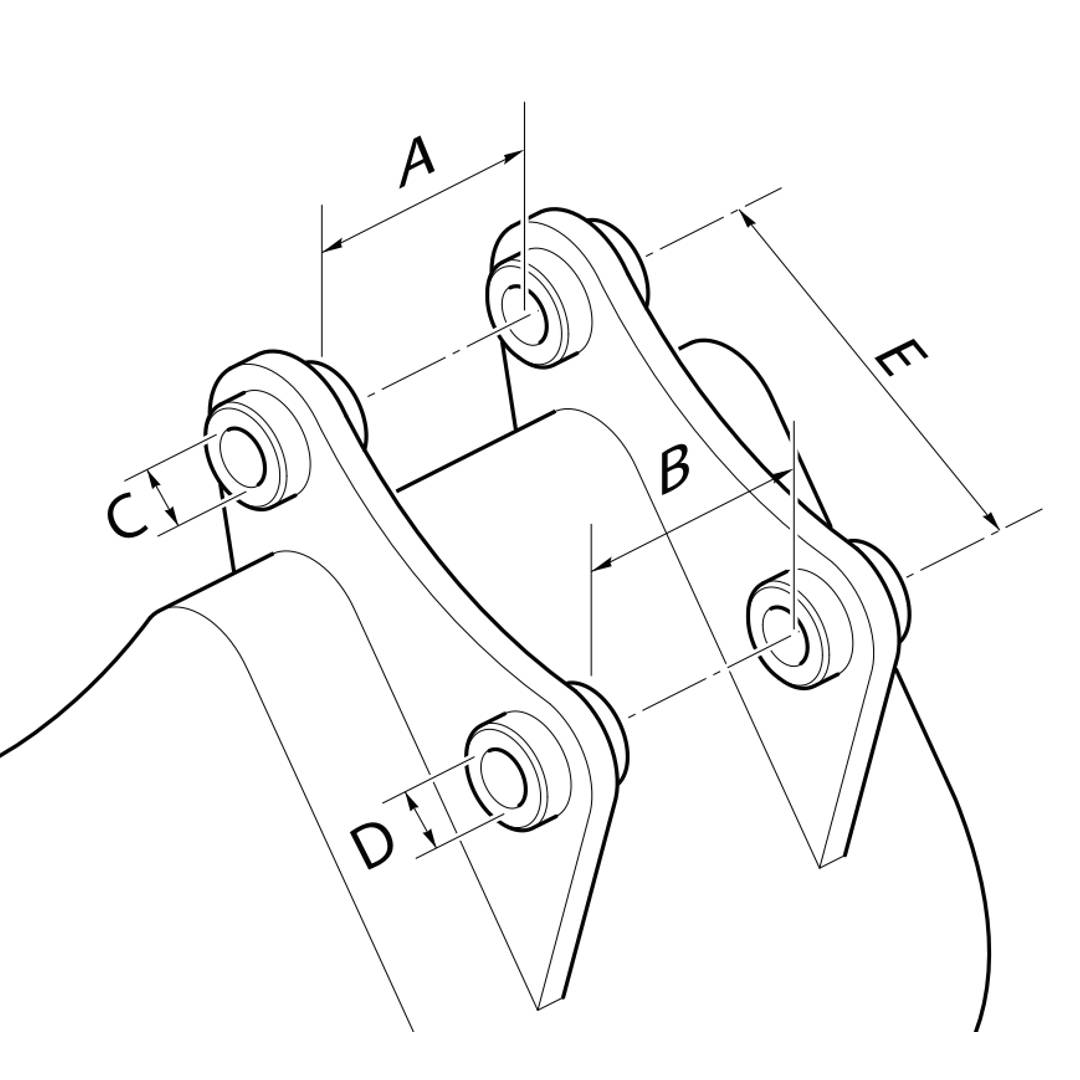

There are a few main pin dimensions that need to be verified to build a mount for an attachment to suit:

Pin Diameter

Dipper/Stick Width

Link Width

Pin Center to Center

For a pinned attachment for a machine without a quick coupler, we would build the attachment to these dimensions to allow for a good fit to the machine. This would mean that it would be a tight fit around the machine and the pin centers would be what the manufacturer requires to enable full movement of the attachment. From The Attachment Company this would require a short lead time in order to build the attachment mount to suit the OEM pin dimensions.

Quick Couplers

Quick couplers are an attachment that is fitted to the excavator to allow the operator to easily change between buckets and other attachments.

Manual Quick Couplers

A manual coupler is manually opened and closed by the operator in order to lock the attachment in place securely. The operator would pick the attachment using the front on, before getting out of the machine to open the coupler and lock in the rear pin. These couplers require the operator to get out of the machine but are a lot faster and easier than manually knocking out the pins of one bucket to put on another.

Hydraulic Quick Couplers

A Hydraulic coupler uses the same concept but is hydraulically opened and closed meaning that the operator doesn’t have to leave the machine while changing attachments. This makes changing buckets or other tools even faster and easier on the job site, saving time and effort.

What does this mean on the attachment side?

Quick couplers make it slightly easier on the attachment side for building a mount. The pins can be welded/fixed in order to prevent more movement/slop from having loose pins. However, we can still provide loose pins in case the attachment ever has to be manually pinned on another machine, or the coupler has to come off the machine to be fixed etc.

Manual couplers tend to be specific to the excavator and pick up the OEM pin dimensions. The distance in between the ears on the attachment isn’t as crucial as long as it is wide enough for the coupler to drop down and grab the pins. A wider space between the ears or bosses isn’t too bad since the coupler will lock the attachment tight in place.

However hydraulic quick couplers usually pick up a range of pin centers and pin diameters on the attachment side. This means that you can usually pick up some attachments that are actually built to suit other machines as long as the dimensions fall in the pick up range of the coupler. And again providing the boss spacing or distance between the ears is wider than the coupler.

For this reason, to try and create faster lead times, we have created a universal standard for each pin diameter. This will allow for faster shipping of machines that are manually pinned and also for machines with a hydraulic coupler (since they pick up a range). For a machine with a manual coupler we will still have to build the mount to suit the specific dimensions.

We have looked at all the machines with a specific pin diameter and made a standard stick width dimension that suits the machine with the widest stick. For machine’s with a narrower stick, we will provide a shim kit in order to achieve a slim fit.

For the pin centers, we have averaged all the pin centers measurements for machine’s with each pin diameter. This means most hydraulic couplers will be able to pick up this center to center measurement. Also manually pinned on attachments will be able to be pinned on normally. The pin center will be slightly different from the OEM dimension, but the difference shouldn’t make much of a difference in most cases.

This will allow us to keep a stock of these standard/universal hitches that we can then adapt to suit the attachment that you need, and ship with a shorter lead time.

Dedicated Quick Connect Style Mounts

In the US there are a variety of machine manufacturers that have their own dedicated coupler styles. They equip the machine with these quick couplers and then it means that you can pick up any of their attachments easily across the range.

Here is a list of some of the more popular manufacturers dedicated coupler systems:

Bobcat Quick X Change

Kubota Style Quick Connect

John Deere Wedgelock Style

Wain Roy Style

Verachtert (CAT) less common

S Type – Tiltrotators

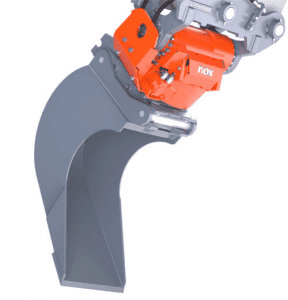

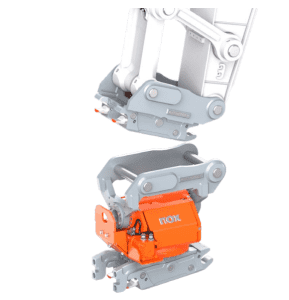

Next we are moving onto one of the newest styles of hook ups for excavators that is more dedicated to the tiltrotator attachments. If you would like some more information on tiltrotator attachments, you can read our complete guide to the NOX tiltrotator here.

Tiltrotators add a lot of extra height on the end of your machine’s stick to enable the tilt and rotation movements of the attachment. This means we really want a quick coupler underneath the tiltrotator that is the most compact, in terms of height.

This is where the S type, or S Lock, couplers come in:

As well as keeping the build height low, the S couplers have standardized dimensions for each pin diameter making it easier to find attachments that you know will suit your coupler.

For example any tiltrotator brand with an S45 coupler will pick up all S45 attachments, no matter the brand. This makes our job as attachment suppliers a lot easier.

The S type coupler is the standard when it comes to tiltrotator attachments. Although other styles are available we always strongly suggest the S type, and some manufacturers have recently switched to only offer tiltrotators with S type couplers.

Because of the reduced build height of these couplers, it means that you can put a standard quick coupler on the machine that is used to pick up the tiltrotator itself. This makes it a lot easier if you ever need to drop off the tiltrotator to do some work where it is not needed.

The term sandwich is used because the tiltrotator is in a coupler sandwich. Since you have the same coupler on top and on bottom, you can pick up all your attachments without the tiltrotator too. So if you have any problems you can drop the tiltrotator and pick up buckets as normal.

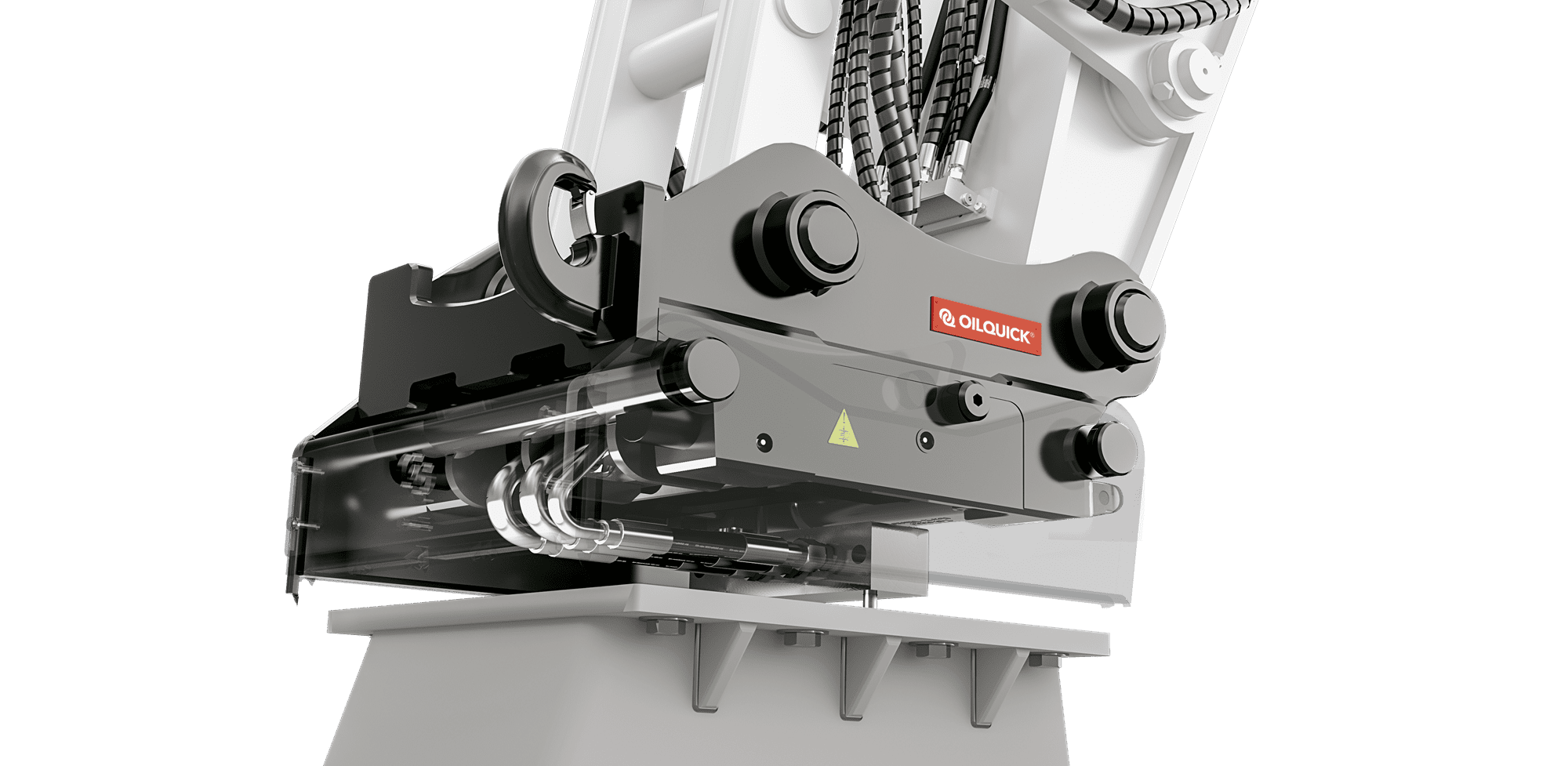

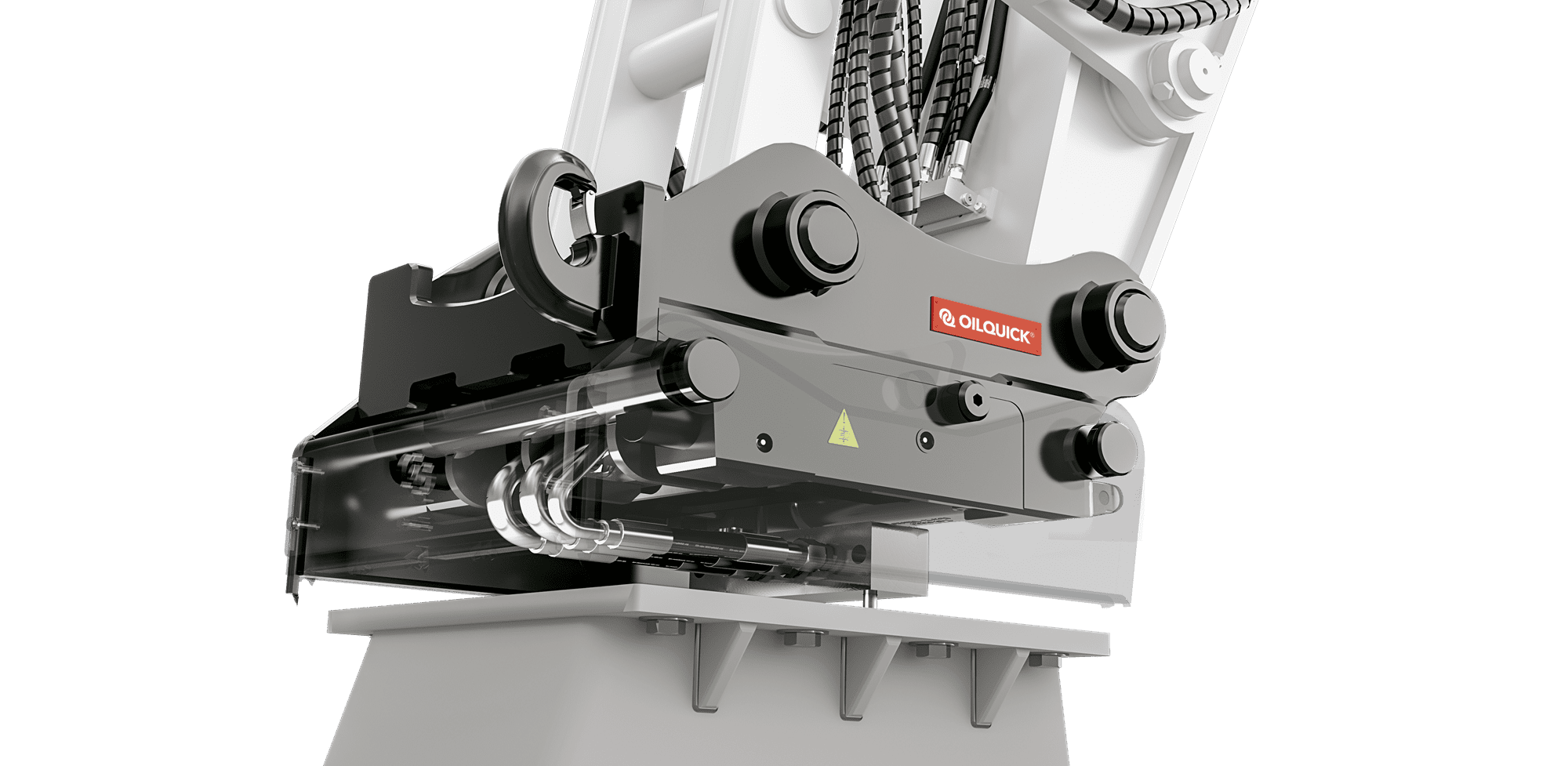

Fully Hydraulic Coupler Systems

Last but not least we are going to look at the fully hydraulic coupler system. “I thought we already covered hydraulic couplers?” You might say. We did. However a fully hydraulic coupler setup runs the hydraulics to power the attachment through the coupler as well. Meaning you can pick up a hydraulic attachment and go straight to work without having to get out and connect hoses.

This is the most advanced system for excavator attachments that greatly reduces time and effort needed to switch between work tools. On job sites where there is a lot of switching back and forward this can save a lot of time and money.

The attachment and the coupler both have a bank of hydraulic connectors. When you pick up the attachment and lock it in place – the hydraulics connect together in a few seconds giving you use of the attachment immediately.

Most tiltrotator manufacturers offer this option on the tiltrotator and also on the top coupler. Meaning you can drop off the full tiltrotator seamlessly without getting out of the machine.

Other than the tiltrotator manufacturers, the main manufacturer of this style of couplers is OilQuick. This is the most advanced piece of excavator technology that has come to the forefront in recent years. With more and more attachment tools available for excavators, the coupler setups are extremely valuable on the job site.

Conclusion

There are various types of excavator mounting systems available making it tricky to determine what you need when looking for an attachment. Hopefully this article explained the different type of mounting systems that are available from simple single pin mounts up to fully hydraulic coupler systems.

If you have any questions, as always you can reach out to us on (941) 212 0037 or through our contact us page here!

Excavator Bucket Pin Size Chart

A large list of pin dimensions from mini excavators up to 50 tons.

I found the information quite useful when you told us that quick couplers are attached to excavators to help the operator change between buckets and other attachments much more easily. Speaking of excavators, I need to get excavating equipment soon to clear the land I plan to use for my holiday house construction. I’ll keep this in mind while I look for an equipment supplier to contact about excavating services soon.

This comprehensive guide on excavator mounting options provides a valuable insight into the diverse choices available. The author’s clear explanations and practical examples, such as the comparison of pin dimensions across different manufacturers, add a touch of real-world experience to the technical details. As someone new to the world of excavator attachments, this article has been a helpful eye-opener, making the seemingly complex subject more approachable.

Thank you, I have just been searching for info approximately this topic for ages and yours is the best I have found out till now. But, what in regards to the bottom line? Are you certain in regards to the source?